How refractometer works

Optical refractive index measurement principle

KxS process refractometers DCM (digital concentration monitoring) employ the physical phenomenon of Refractive Index to define liquid concentration. In-line methodology provides benefits, including data reliability, accuracy, and consistency; fast and repeatable measurements; and tight control of the process.

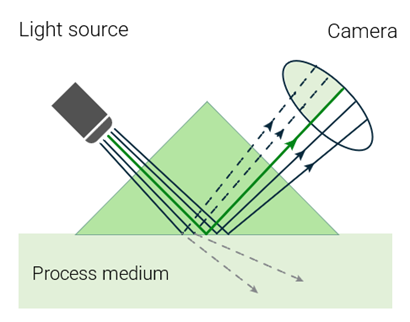

Optical concentration measurement is based on Snell’s law and the critical angle of total reflection to provide precise readings. Light is emitted from an LED and directed towards the interface between an optical window and the liquid being measured. As the concentration of the liquid changes, specific angles of the light are totally reflected and partially reflected back, producing light and shadow interface that is captured by a digital camera sensing element.

This interface is detected by the light-activated camera pixels and converted into refractive index (RI). The RI values can be directly used or further translated into any concentration units, such as percentage by weight, density, or Brix (sugar content). This method ensures that measurement signals are provided instantaneously, allowing for real-time process control.

Reliable inline concentration measurement

Transforming refractive index principle into fully functional inline process refractometer readings requires expertise and experience to meet diverse user demands and address various process conditions. These conditions differ across industries and can be influenced by factors such as process stream characteristics, heat transfer, temperature variations, pressure, flow, contaminants, and corrosion.

Through continuous refinements over decades, our inline refractometers are engineered to operate reliably in customers’ process conditions due to, e.g.:

-

Optics: We have replaced traditional fiber optics, prone to breakage, with innovative, non-breakable design.

-

Straight pipe connection: Our design innovation offers significantly better flow velocity on measurement window compared to traditional elbow-mounted systems, and ease of mounting.

-

Modern measurement outputs: dual analog 4-20mA and digital Modbus TCP.

-

Conformance: In industries with stringent hygiene requirements, our 3-A and EHEDG design secures contamination-free operation.

-

Safety: In pulp mill installations, our PASVE® ball-type mounting valve allows for the safe and easy removal of the device without process shutdown.

When successfully designed and implemented, inline refractometers offer significant advantages for process control across semiconductor, food, pharmaceutical, bioprosessing, chemical, petrochemical, and pulp and paper processing industries. This technology enables direct inline measurement, providing the quickest, most reliable measurement data without delay.

Book a consultation

Our engineers collaborate with customers and can help you optimize your process. We help you identify areas for improvement, increase yield, reduce waste, and implement the right solution, no matter the application or complexity.

Book a consultation with our experts and let’s find together the best solution for your application needs!