KxS inline Brix refractometers for sugar refining and processing: Know your Brix

Sugar production is a complex and highly energy-demanding process, encompassing various sub-processes. Brix measurement is a critical aspect of this process, serving as a key indicator of sucrose content and quality. By accurately measuring Brix, sugar processors can optimize sugar extraction, crystallization, and refining processes, leading to higher sugar recovery, superior product quality, and increased profitability.

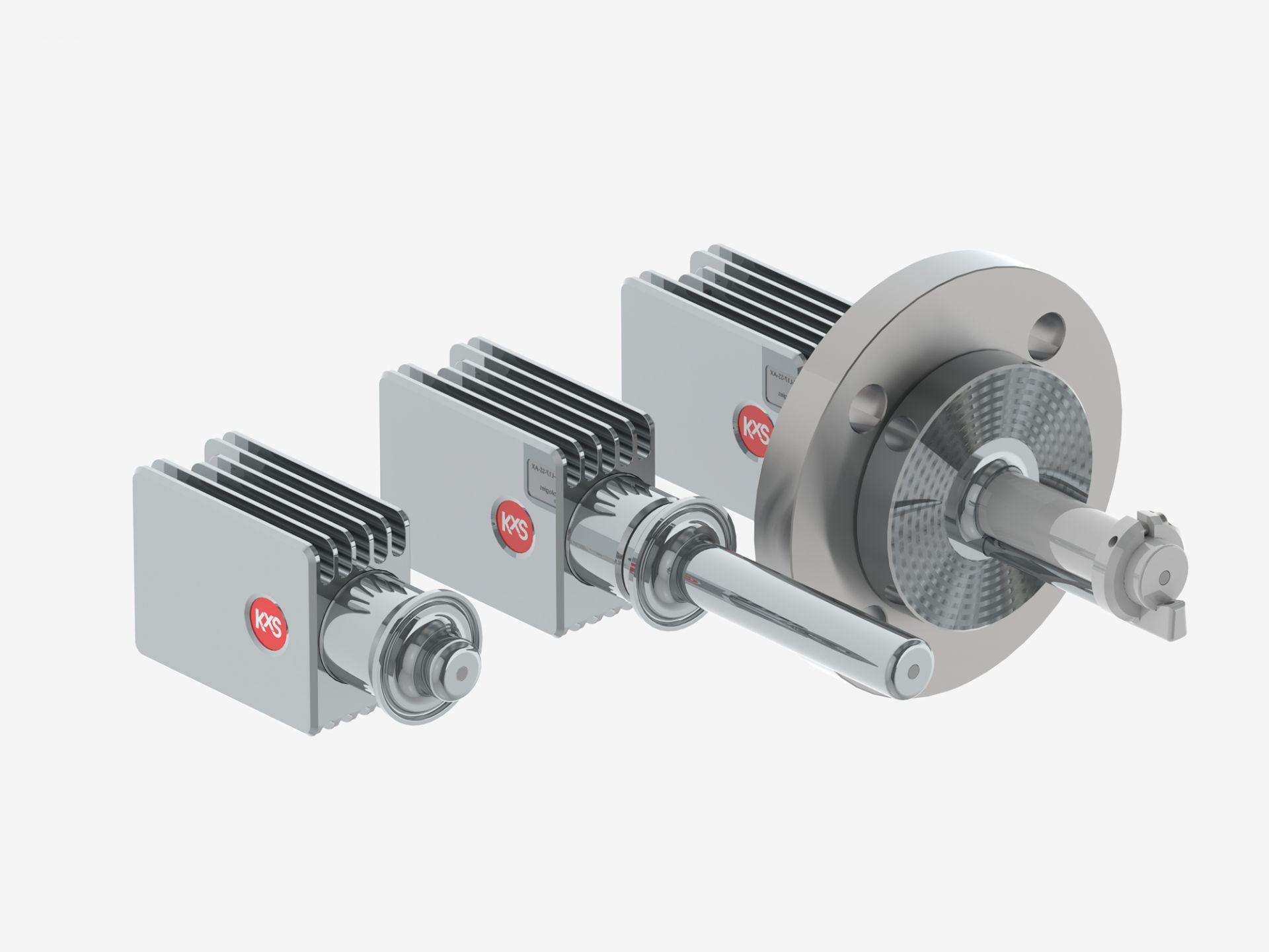

With over 40 years of experience, KxS deeply understands the significance of Brix measurements and their applications. Our expertise empowers sugar industry professionals to make informed decisions and produce exceptional sugar products.

Applications

- Cane sugar milling and refining

- Beet sugar milling and refining

- Liquid sugar production

- Molasses

- Crystallization

Why choose KxS inline Brix refractometers?

KxS inline Brix refractometers are used throughout the entire sugar production process. Whether the source is sugar cane or sugar beet, our inline refractometers monitor Brix from initial processing and refinement to syrups, and final liquid and crystallized products.

Key features

- Rugged construction that withstands the harsh conditions of sugar process environments

- Measurement is unaffected by bubbles or formed crystals

- Reliable integrated temperature compensation to ensures accurate readings regardless of temperature fluctuations

- Versatile options of industrial and sanitary process connections for inline pipe and vacuum pan installations

Cane sugar process optimization

- Diffusion: Refractometer rapidly detects process disturbances during diffusion. By accurately controlling concentration levels, it minimizes the quantity of water introduced, thereby reducing the energy required for subsequent evaporation. This leads to significant energy savings and better efficiency. Additionally, the refractometer facilitates precise calculations of diffuser plant output, ensuring optimal performance.

- Evaporation: During evaporation, the KxS inline brix refractometer plays a critical role in regulating product flow to match the evaporator’s capacity, further conserving energy. The refractometer’s real-time data can also be used to control steam flow, optimizing the evaporation process and efficiency.

- Crystallization: Refractive index technology is the best way for controlling and monitoring crystallization. The refractometer selectively monitors the concentration of the mother liquor, maintaining the supersaturation state necessary for crystal formation.

Beet sugar refining optimization

The KxS inline brix refractometer is integral at various stages of the beet sugar refining process. Its measurements are reliable despite entrapped air bubbles, undissolved components, or color variations—common sources of error for other instruments. This reliability ensures accurate and real-time concentration information, facilitating better process control, increased productivity, and improved product quality.

Stage-specific applications:

- Affination: Enhances the separation of sugar crystals from syrup.

- Decolorization: Ensures effective removal of color impurities.

- Evaporation: Optimizes the concentration process.

- Recovery: Improves the efficiency of sugar recovery.

- Crystallization: Reliable monitoring of mother liquor concentration is crucial for the control of crystallization pans to ensure consistent crystal size, increased yield and eliminating the need for costly reprocessing. Moreover, the refractometer helps avoid the false grain, reducing the necessity for product screening.

"KxS DCM-20 is an exceptionally robust Brix monitor, perfect for all sugar measurements in refineries. Its precise measurement and easy start-up process, combined with the latest sensor technology, ensure reliable performance for decades."

Book a consultation

Our team of engineers offers application and Brix instrumentation supervision for the retrofit, expansion, modernization, and construction of new and existing sugar production processes and automation.

Contact us and schedule a consultation and take the first step towards enhancing your sugar production process.